Low-carbon Sustainable Product

Loading...

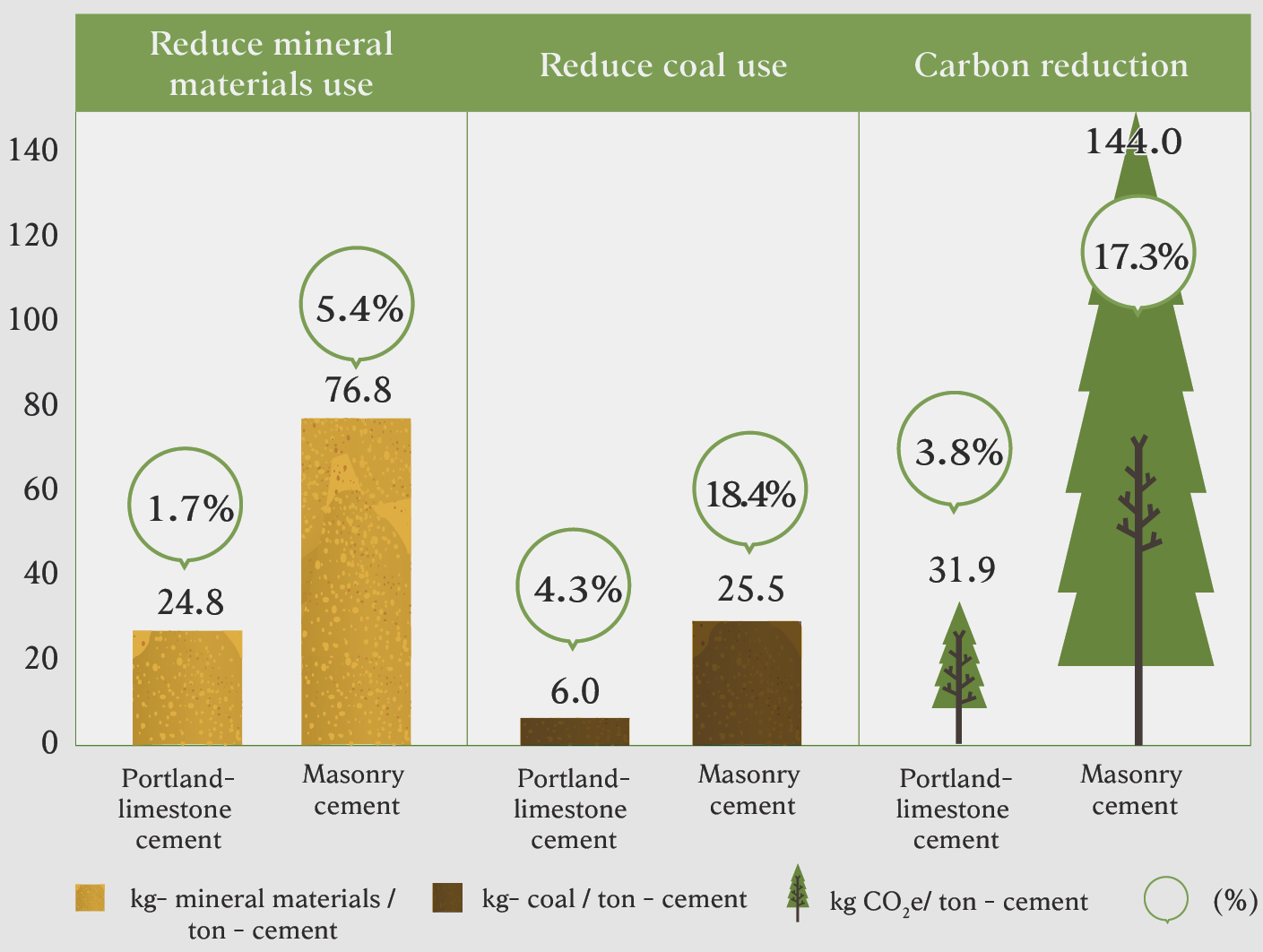

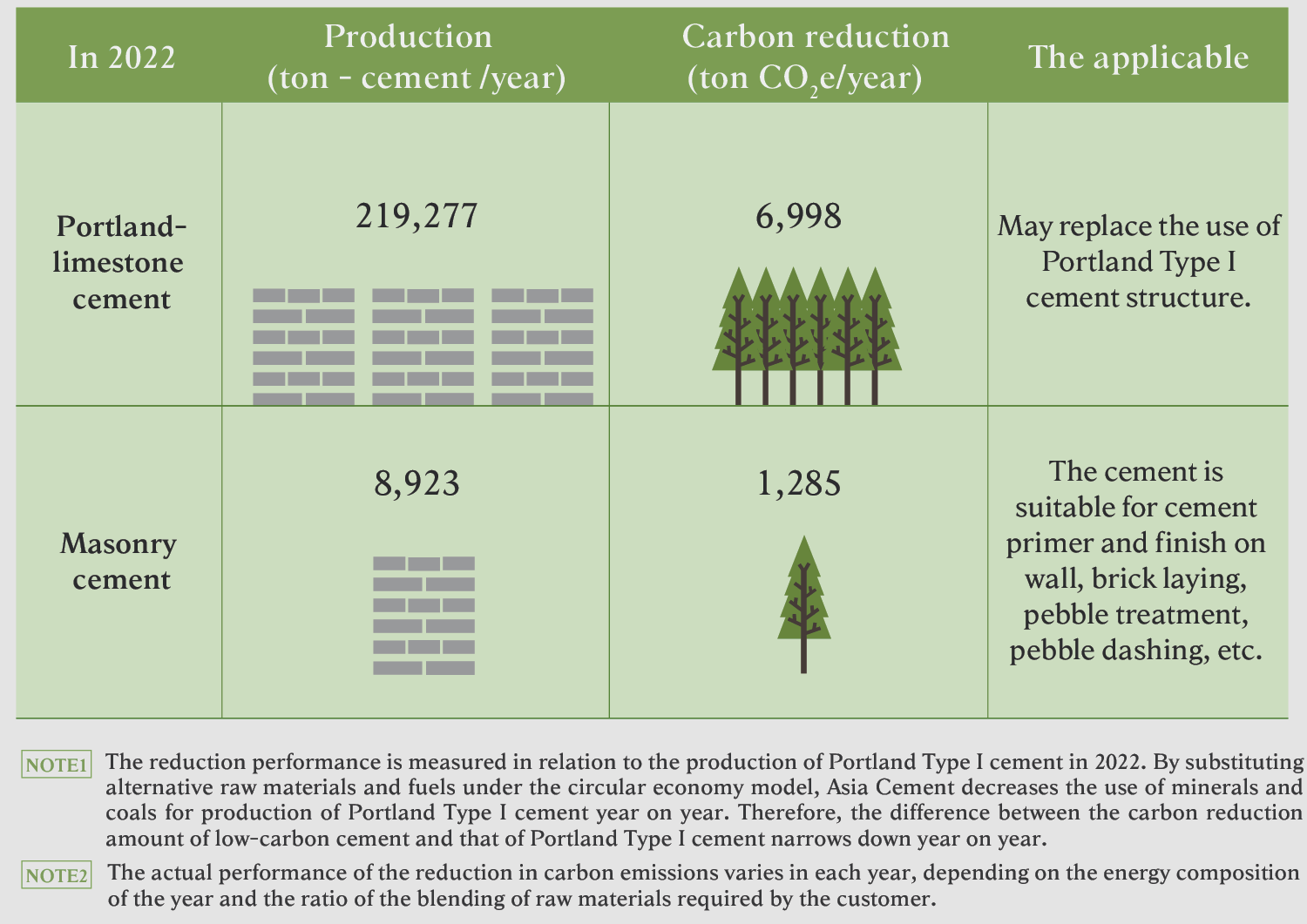

According to the needs of buck cement used by concrete and bag cement used by cement work, Asia Cement was leading the industry in Taiwan and launched low carbon products of “Portland-limestone cement” and “Masonry cement” . In 2022, the Company started a new era of low carbon products in the industry in Taiwan with the outstanding results of actively promoting the products to customer groups.

Portland-limestone cement (PLC)

The Asia Cement exclusively developed Portland-limestone Cement (PLC) product, is a blended cement with a high limestone content, which can be used in general buildings, bridges, paving, precast concrete, and large-scale concrete. The product not only retains the performance of Portland Cement, but can also effectively reduce greenhouse gas emissions, resulting in a low-carbon sustainable product.

Through a comprehensive experimental plan, Asia Cement took into account the front-end "cement quality" performance and the back-end "concrete properties". After two years of testing, Asia Cement finally successfully developed Portland-limestone Cement and established sales of 210,000 tons to the United States.

Asia Cement initiated the amendment of CNS 15286 blended hydraulic cement national standard and increased the types of Porland limestone cement and triple blend cement to link with international domain. The standard was officially announced in August of 2022. The amendment of regulations of cement products inspection was passed in January of 2023.

Masonry Cement

Asia Cement led the industry since 2011 to promote the sales of low carbon Masonry cement. The cement is suitable for cement primer and finish on wall, brick laying, pebble treatment, pebble dashing, etc. plus superior constructability and anti-crack feature. Since it was difficult to ask cement workers to change their habbit, it was not easy to promote the product.

Asia Cement participated “2022 Tainan International Green Industry Show” and “Taipei International Construction Material and Products Show” to promote Masonry cement. In 2022, a total of 7,871 tons of low carbon Masonry cement was sold by Asia Cement under its aggressive promotion, a growth of 5 times more than that of last year.

2022 Low Carbon Cement Highlights

Low carbon sustainable industrial chain

Asia Cement reinvestment Ya Tung Ready-Mixed Concrete Co., Ltd. Nine plants of Ya Tung Ready-mixed Concrete have received GRMC label issued by Taiwan Construction Research Institute, five plants received Label of Green Construction Material H Category issued by Architecture and Building Research Institute, Ministry of the Interior. It also received vertifications of ISO 14064-1, ISO 14067 carbon footprint and ISO 14046 water footprint, certification of BS 8001 circular economy.

Ya Tung Ready-mixed Concrete assisted EPA of Executive Yuan drafted ready-mixed concrete product carbon label Product Category

Rules (PCR) and received concrete product carbon label certificate in May of 2022. For the same strength, carbon can be reduced by 25% and 28% from low carbon ratio, comparing to ordinary ratio.